Reliable vapor recovery system for 0 to 10 MCFPD

Today's vapor recovery systems are designed for the high rates associated with gas flashing from crude oil as it enters atmospheric stock tanks. Low rates of vapor have traditionally been incinerated, hence there exists a lack of reliable low rate vapor recovery equipment.

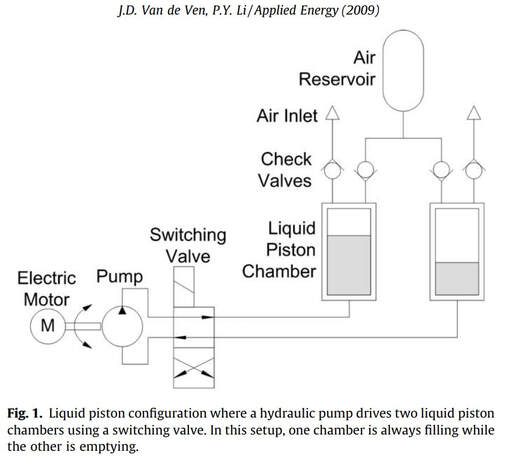

Due to heightened regulation of Greenhouse Gas Emissions, low volume vapor recovery is more desirable than incineration. Consequently our industry needs low rate vapor recovery options. The Liquid Piston Compressor is such an option that utilizes highly reliable equipment and few moving parts, namely a water pump that fills up a vertical pipe. As this pipe fills, gas above the liquid is compressed and flows out the top through a check valve. The pump takes suction through a second cylinder with fugitive vapors filling the void created as the water leaves. Swap sides and repeat.

The Liquid Piston Compressor dates back to 1906, but has few if any current uses due to the availability of other types of compression. Pump and valve control and over-displacement of working fluid were also problems that are now solved by current technology, some of which Encline has patented. One result is 99% volumetric efficiency, and 100% turndown ratio.

Due to heightened regulation of Greenhouse Gas Emissions, low volume vapor recovery is more desirable than incineration. Consequently our industry needs low rate vapor recovery options. The Liquid Piston Compressor is such an option that utilizes highly reliable equipment and few moving parts, namely a water pump that fills up a vertical pipe. As this pipe fills, gas above the liquid is compressed and flows out the top through a check valve. The pump takes suction through a second cylinder with fugitive vapors filling the void created as the water leaves. Swap sides and repeat.

The Liquid Piston Compressor dates back to 1906, but has few if any current uses due to the availability of other types of compression. Pump and valve control and over-displacement of working fluid were also problems that are now solved by current technology, some of which Encline has patented. One result is 99% volumetric efficiency, and 100% turndown ratio.

Why not sell your vapors instead of burning them?

Could be too costly, but just like any new technology, the costs are initially high until mass production begins.

Encline will support industry with both engineering and our patented control technology, and looks for development partners to jointly design, build, and test Liquid Piston VRU’s

Encline will support industry with both engineering and our patented control technology, and looks for development partners to jointly design, build, and test Liquid Piston VRU’s

Smartphone Monitoring |

Scada / MQTT |

|

Like other Encline products, the Liquid Piston VRU will utilize a controller that is an Edge Computing device, and speaks all popular Modbus protocols. It also features newer MQTT capability.

|