Collects basic compressor data then uses Artificial Intelligence and Data Analytics to create KPI’s that identify problems such as bad valve location

Gas compressors are about the only oilfield devices that don’t have operating data captured by SCADA. Why be satisfied with only knowing the compressor is running when Encline can provide over 100 critical data points for easy operator SCADA collection?

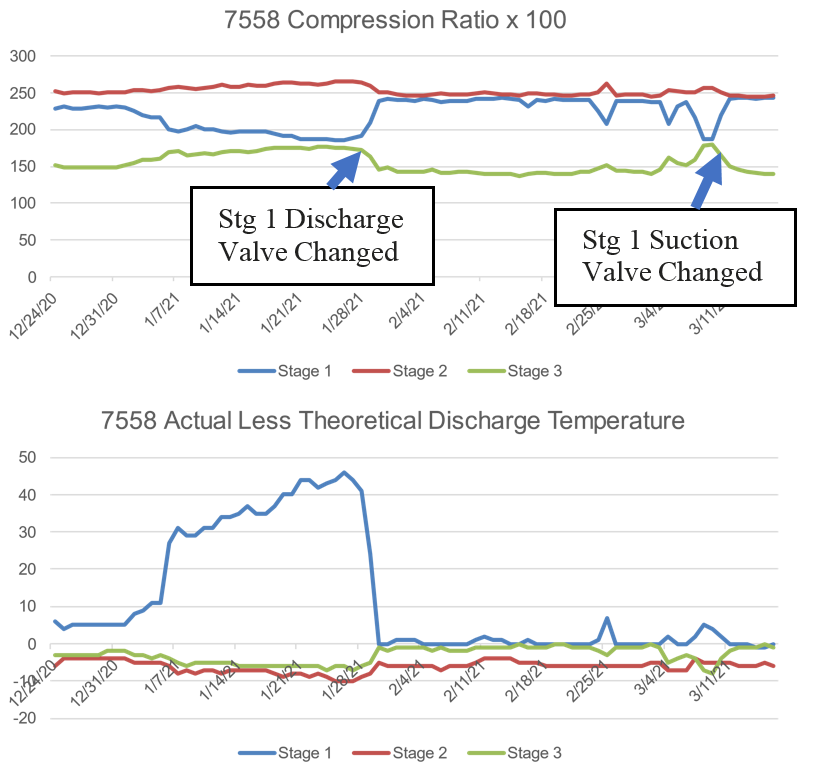

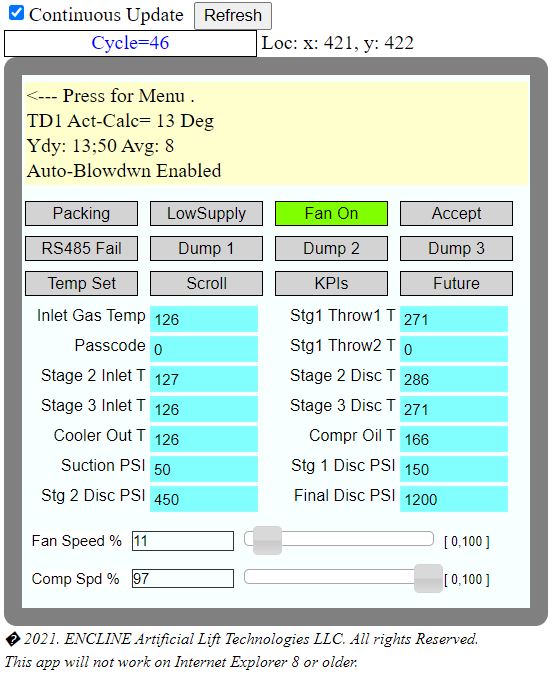

In addition to normal compressor temperature and pressure information, Encline collects temperatures on the inlet of each compression stage and the final skid discharge temperature. Using Artificial Intelligence and robust Data Analytics, this edge computing device calculates KPI’s that identify problem compressor valves by stage, whether suction or discharge. Rules-based decision making is used to provide alarms such as hung-open scrubber dumps and improperly performing suction pressure controllers.

Operator SCADA personnel will appreciate that every compressor connected to the Encline Gas Compressor Expert will have an identical MODBUS register map.

In addition to normal compressor temperature and pressure information, Encline collects temperatures on the inlet of each compression stage and the final skid discharge temperature. Using Artificial Intelligence and robust Data Analytics, this edge computing device calculates KPI’s that identify problem compressor valves by stage, whether suction or discharge. Rules-based decision making is used to provide alarms such as hung-open scrubber dumps and improperly performing suction pressure controllers.

Operator SCADA personnel will appreciate that every compressor connected to the Encline Gas Compressor Expert will have an identical MODBUS register map.

Example: Two KPI's Detect Bad Valves

Additional Encline Sensors

|

Counting scrubber dumps can aid in setting cooler louver positions as excessive scrubber cycling can be alarmed. Counting the dump duration identifies hung scrubber dump valves and creates a local alarm. Pressure switches measuring the supply gas pressure and the compressor packing case pressure are helpful in sensing other compressor problems including leaking packing cases. These and other compressor problems are relayed through the operator’s SCADA system to their personnel.

|