A simple yet intelligent system for pump or pumping unit control with shutdown annunciation and Scada comms

|

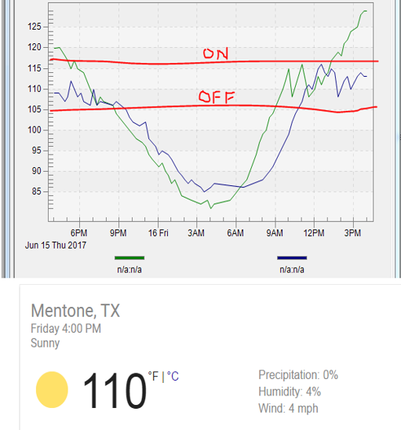

Due to the widespread availability of various sensors that detect operational problems at wellsites, it is sometimes difficult for lease operating personnel to quickly determine the cause of an equipment shutdown. In many cases, an oilfield electrician has provided a system of relays that do not give an indication as to what caused a shutdown. Perhaps the pumping unit is simply not operating as part of a time cycle, and there is no shutdown. A simple, low cost, yet reliable system has been designed that resolves these issues while providing the ability to communicate with Scada and the more advanced internet based systems of the future. Additional sensors can be added to collect flowline, tubing, and /or casing pressure, or vibrations sensors can detect wear on mechanical components.

|

Options for Smart ESD Packages

|

Option 1

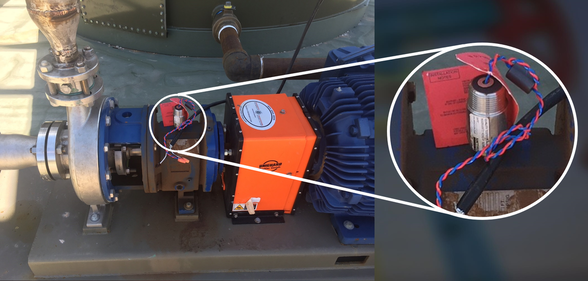

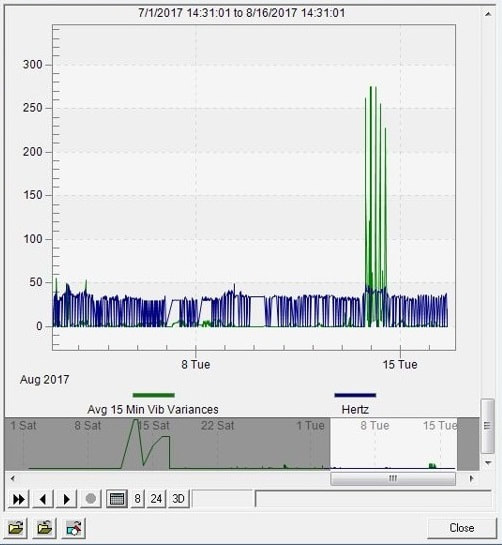

Metrix Vibration Transducer is incorporated to detect mechanical issues before they become severe. Candidates are rotating equipment such as centrifugal pumps and rotary vane or screw compressors. This version incorporates the control of a VFD cooling fan, as improper cooling fan operation is known to cause premature VFD failure. Plugged air filters are detected as is cooling fan failure. |

Low-cost, field-proven industrial PLC

Smart ESD from ENCLINE provides a variety of informative shutdown annunciations as well as optional packages to further protect operator equipment:

- Simple annunciation at wellsite HMI and on smartphone webpage hosted by the device

- Provision for standard shutdowns like high / low flowline pressure, high separator level, low / high tank level, low oil level, high enviropot level, etc.

- All values easily polled by most any Scada system

- PLC fluent in multiple Modbus protocols and MQTT