Reduce gas interference and rod wear

Maintain production with fewer rod strokes

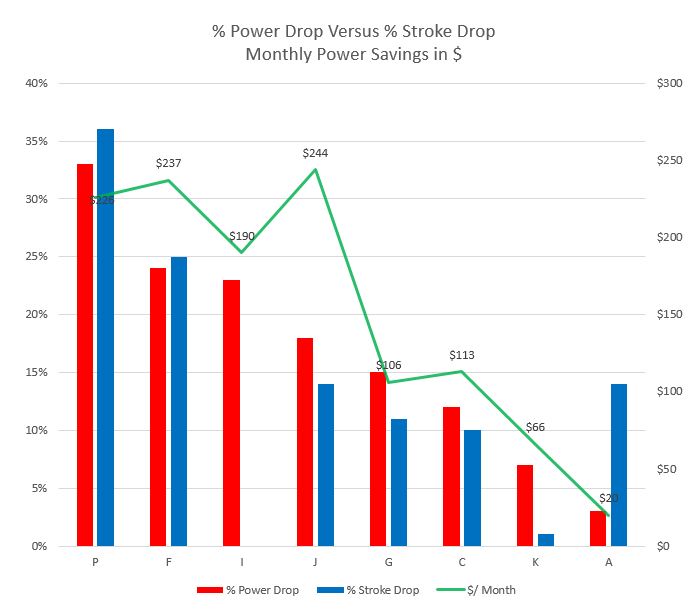

Reduce power consumption

Maintain production with fewer rod strokes

Reduce power consumption

Rod pumping unit being controlled by ENCLINE Pump Stroke Optimization™

Pump Stroke Optimization™ continuously “learns and adjusts" to the changing flow regime of a horizontal oil well. Working with the existing rod pump controller, PSO delivers an alternate speed signal to the VFD that decreases pump slippage, increases pump fillage, and improves rod loading.

The optimum upstroke and downstroke speeds differ for every horizontal oil well. Further, the optimum speeds change over time due to the dynamic nature of the fluid flow in each well. Pump Stroke Optimization™ automatically computes the optimum rate for both upstroke speed and downstroke speed in real time.

Encline's Pump Stroke Optimization™ algorithms recognize transient slug and wave flow behavior as short term events. PSO algorithms regularly adjust the maximum and minimum pumping speeds to be consistent with the well’s normal production. The results: fewer low pump fillage events, lower magnitude low fillage events, and higher overall pump fillage.

Encline's Pump Stroke Optimization™ algorithms recognize transient slug and wave flow behavior as short term events. PSO algorithms regularly adjust the maximum and minimum pumping speeds to be consistent with the well’s normal production. The results: fewer low pump fillage events, lower magnitude low fillage events, and higher overall pump fillage.